Design and craft

Customized manufacturing

High quality

Design and craft

Customized manufacturing

High quality

Quality in every detail

Natural stone factory

Natural stone factory

Gerloff Natursteinmanufaktur is located in Cornberg, Hesse, and has been producing high-quality natural stone products for over 100 years. Since our founding we have specialized in the processing of marble, granite, sandstone and other natural and artificial stones. Our experience makes us a strong partner in stone processing. In addition to our own Gerloff products, we can manufacture a wide range of products using the latest machinery and specialized manual labor. In addition to vanities, showers, floor and wall coverings, we also offer custom kitchen countertops, window sills, stair treads and much more.

Your perfect partner

High quality

Our modern production facilities and our experienced team of experts is your perfect partner for the production and processing of the highest quality natural stones. We attach particular importance to high quality and individual design in order to meet the wishes of our customers at all times. Thus, in addition to almost any natural stone, we also offer customized solutions for your individual request.

Sustainability and environmentally friendly production are particularly important to us in everything we do. Thus, the natural stones are sourced from carefully selected quarries that are subject to strict environmental standards. During production, too, attention is paid to resource-saving processing. This applies especially to the use of energy and water for cooling the machines.

Gerloff individual manufacturing: High quality and unique design of natural stone products.

Your perfect partner

High quality

Our modern production facilities and our experienced team of experts is your perfect partner for the production and processing of the highest quality natural stones. We attach particular importance to high quality and individual design in order to meet the wishes of our customers at all times. Thus, in addition to almost any natural stone, we also offer customized solutions for your individual request.

Sustainability and environmentally friendly production are particularly important to us in everything we do. Thus, the natural stones are sourced from carefully selected quarries that are subject to strict environmental standards. During production, too, attention is paid to resource-saving processing. This applies especially to the use of energy and water for cooling the machines.

Gerloff individual manufacturing: High quality and unique design of natural stone products.

Precise craftsmanship

Our factory

Gerloff is a leading company in the natural stone industry. Our Cornberg plant has a total area of 30,000 m². With a wide range of CNC-controlled machinery, including waterjet cutting machines, Baveloni milling centers, bridge saws and edge processing centers, Gerloff is capable of processing all types of slabs of natural and artificial stone, as well as granite. Coupled with precise manual work in the individual manufacturing of products, we offer our customers a wide range of individual and high-quality design options.

Our expert team of 25 excellently trained natural & cast stone mechanics offers a wide range of surface finishes. Take advantage of our large stock of natural stones or send us your individual request. Through our long-standing and close-knit network, we are able to provide you with almost any stone from the most remote regions of the world.

Our expert team of 25 excellently trained natural & cast stone mechanics offers a wide range of surface finishes. Take advantage of our large stock of natural stones or send us your individual request. Through our long-standing and close-knit network, we are able to provide you with almost any stone from the most remote regions of the world.

Manufacturing steps

Production line

- Check and select raw materials: The natural stone slabs are checked for defects and cracks. In this way, we ensure that only high-quality raw materials are used for processing.

- Cutting: The natural stone slabs are cut to the desired size with a bridge saw or a CNC-controlled water jet machine.

- Surface finishing: The natural stone slabs are either polished, honed, flamed or brushed to achieve the desired surface texture.

- Edge processing: The edges of the natural stone slabs are processed to achieve the desired shape and thickness. This can be done by hand or with a CNC-controlled machine.

- Drilling and milling: Holes and recesses are drilled or milled in the natural stone slabs to prepare them for the installation of faucets, sinks or other elements.

- Quality control: After each stage of production, the natural stone slabs are checked for defects, cracks and other quality problems. This is how we ensure that they meet the high standards of our manufacturing.

- Packing and shipping: The finished natural stone slabs are properly packed and prepared for shipping.

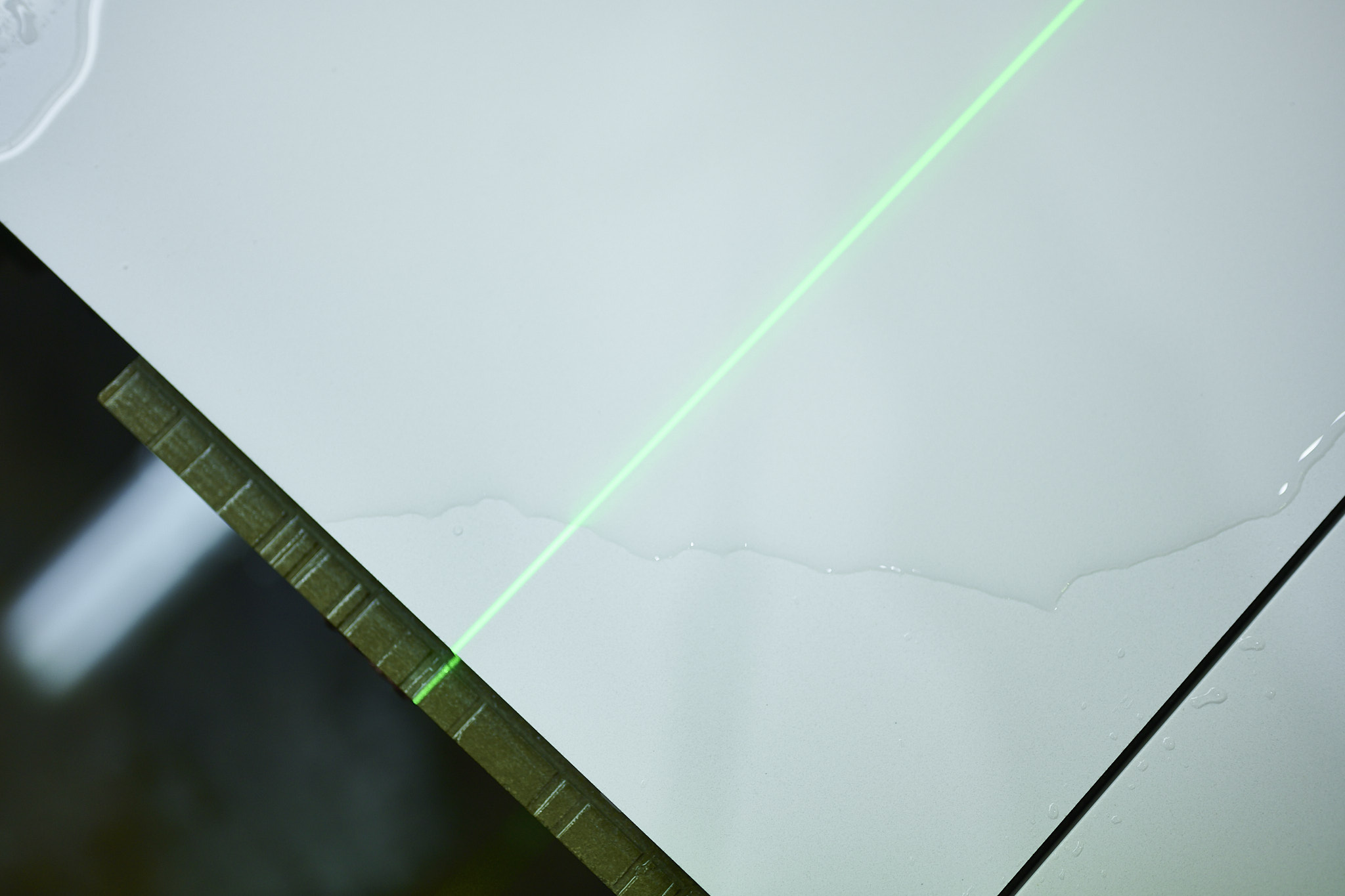

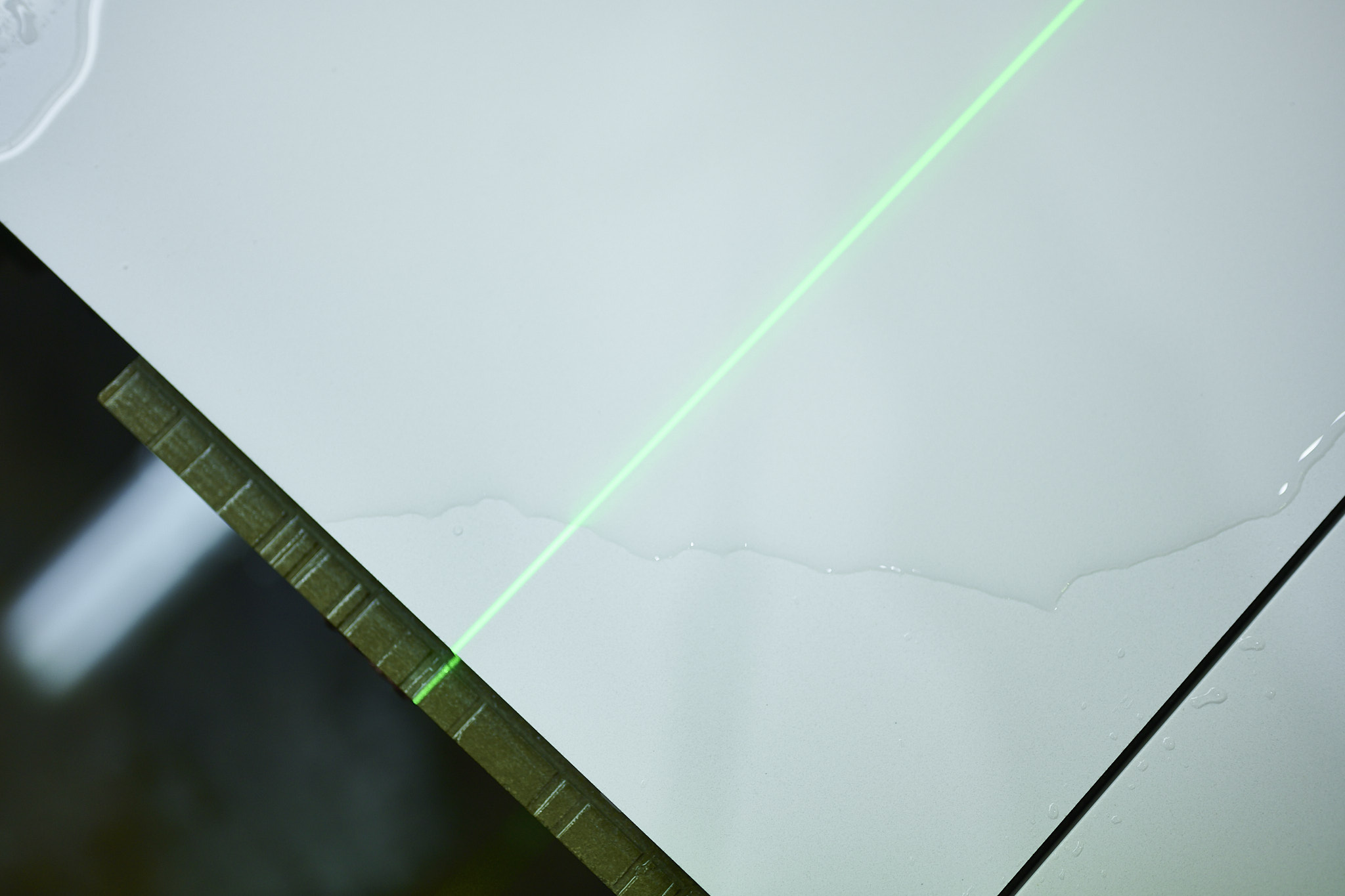

Quality in every detail

Final inspection

Probably the most important step in production is the final inspection. Here, our trained personnel perform the last look in the 4-Eyes Principle. Attention is paid to dimensional and processing accuracy down to the millimeter. This is how we guarantee the quality of each individual piece and do justice to even the most demanding project.

Proud partner

Our references

Contact us

© Copyright 2023